13.10/2023

POLEMA presented at the“BIOTECHMED” its innovative medical products

11.07/2023

POLEMA at INNOPROM in Ekaterinburg

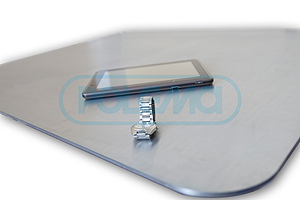

Chromium sputtering targets and evaporable cathodes

JSC POLEMA is a leading global producer of sputter targets and evaporable sources (cathodes) made from refined electrolytic chromium. The company's share in this segment of the global market is approximately 30%.

Use

Products made from chromium are used in various technologies for the physical deposition of thin films and functional coatings (the PVD method) in the production of electronic components, displays, and tools, and in the vacuum chroming of watches, parts of household appliances, the working surfaces of hydro-pneumcylinders, slide valves, piston rods, tinted glass, mirrors, car parts and accessories, and other machines and devices. When depositing strengthening coatings from ionized plasma using the method of vacuum-arc vaporization of a cathode or by magnetic target sputtering, chromium is used as an adhesive substratum and, in combination with other materials, is used for multi-layer and nanostructural multi-functional wear-resistant coatings. High-quality large-size planar targets made from electrolytic refined chromium (ERC) are used by leading manufacturers of plasma and liquid-crystal displays to deposit metallic conductors during the formation in monitor matrices of thin-film transistors (TFT technology).

Production

Production process:

Chromium ERCr flakes → powder → compact stock → ERCr-PM product

The powder undergoes a special treatment that ensures material purity equal to that of the base ERCr chrome.

Compaction is done in the following manners:

- hot isostatic pressing (HIP);

- when necessary, rolling of sintered semi-finished products is performed (R).

Final tooling is done in accordance with the client's request.

| Brands |

Cr, %, minimum |

Admixtures, ppm, maximum | ||||||||

| O | N | C | S | Fe | Si | Ni | Al | Cu | ||

| ERCr 99,9-PM | 99,9 | 350 | 100 | 200 | 30 | 500 | 100 | 100 | 70 | 40 |

| ERCr 99,95-PM | 99,95 | 200 | 50 | 100 | 20 | 250 | 50 | 40 | 30 | 30 |

| ERCr 99,97-PM | 99,97 | 100 | 50 | 70 | 20 | 100 | 20 | 10 | 20 | 20 |

| ∑ of metallic admixtures Al, Fe, Cu, Ni, Si, Ca, K, Li, Mg, Mn, Mo, Na, Pb, Ti, W, Zn and others 300 ppm, maximum | ||||||||||

| ERCr 99,99-PM | 99,99 | 100 | 50 | 70 | 20 | 50 | 10 | 5 | 5 | 10 |

| ∑ of metallic admixtures Al, Fe, Cu, Ni, Si, Ca, K, Li, Mg, Mn, Mo, Na, Pb, Ti, W, Zn and others 100 ppm, maximum | ||||||||||

PM – Powder Metallurgy

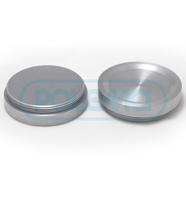

| Shape of treated product | Diameter, mm | Thickness, mm | Width, mm | Length, mm |

| Plate | - | From 5 to 50 | Up to 1400 | Up to 1700 |

| Disc, ring | From 65 to 400 | From 5 to 50 | - | - |

| Rod, cylinder | From 15 to 65 | - | - | Up to 600 |

The following allowances for dimensions are applied, unless otherwise requested by the client, in mm: diameter ± 0.25; thickness ± 0.2; length and width, up to 100 ± 0.15; from 100 to 500 ± 0.25; from 500 to 1000 ± 0.4; more than 1000 ± 1.0.