13.10/2023

POLEMA presented at the“BIOTECHMED” its innovative medical products

11.07/2023

POLEMA at INNOPROM in Ekaterinburg

Progressive materials for multi-functional vacuum coatings

V.V. Rodionov, N.V. Bogolubov, E. A. Root

POLEMA JSC, Tula, RF

Subject: application fields of materials for multi-functional vacuum coatings, characteristics of sputtering targets and evaporable sources used for technologies of physical deposition of hardening, protective, decorative and light-reflecting coatings, resistive, switching and transparent electro conductive films.

POLEMA JSC is the leading Russian enterprise of powder metallurgy producing refractory metals, composite materials, metal powders, sputtering targets and other products of powdered metals and alloys.

Since 1980 Russia's largest complex for production of alloyed and pure metal powders with the capacity of 3,000 tons per year operates as the part of the company. The enterprise produces more than 140 grades of powders based on nickel, cobalt, molybdenum, copper, zink, stannum, alloyed powder steels, surfacing powder bands and wire which are designed for alternative repair techniques and machines parts hardening.

Our comprehensive range of products features great performance in sputtering, surfacing, thermodiffusion chromizing or chrome-colorizing, surface hardening per abrasive steel shot.

In recent years operating as a part of Industrial Metallurgical Holding (IMH), POLEMA JSC has been successful in carrying out numerous challenging projects for developing and production of core materials designed for physical vapour deposition (PVD), hardening, protective, decorative, light-reflecting coatings, resistive, commutation and transparent electrically conductive films.

1. Application of sputtering targets and evaporable materials

| Material | Application |

| Chromium ERCr-1 | Microelectronics, mechanical engineering. Thin-film layers of microcircuits, production of hardening, protective layers, chromium alloying of surfaces by means of thermal, electron-emitting and laser vacuum evaporation. |

| Chromium ERCr-0 | Microelectronics, mechanical engineering. Thin-film layers of microcircuits, highly refined chromium alloying of surfaces by means of thermal, electron-emitting and laser vacuum evaporation. |

| Chromium ERCr99,9-PM | Building sector, production of consumer goods. Protective and decorative coatings for furniture and building accessories, junk jewelry produced by magnetron sputtering or arc ionic deposition. |

| Chromium ERCr99,95(99,99)-PM |

1. Mechanical engineering and tooling industry. Hardening metal and nitride nanocomposite coatings for parts of machines, equipment, cutting and forming tools. Ionic implantation per magnetron sputtering and arc ionic deposition. 2. Microelectronics, display production. It’s used as a surfacing material for resistive films and commutation structures of microcircuits; surfacing of thin-film chromium electrodes in matrixes of large-size LCD and plasma displays. 3. Automobile industry, household appliances, watch producing industry and other industries. Protective and decorative coatings of wheel discs, clads, automobile accessories, sanitary ware. Antiglare back mirrors. Vacuum chromium coating of hydraulic cylinders, guide bars, components of household appliances, watch cases, medical devices and other parts of machines and equipment. 4. Black-out and reflective films for architectural glass and glass packaging. |

| Molybdenum M99,95-PM |

1. Mechanical engineering and tooling industry. Hardening monophase and nanocomposite nitride and carbide coatings of МoC, MoN, (Mo2C)N type for parts of machines, cutting and forming tools. Ionic implantation per magnetron sputtering and arc ionic deposition. 2. Microelectronics, production of nanostructured solar elements, LSD, digital cameras. |

| Tungsten W99,95-PM |

1. Mechanical engineering and tooling industry. Hardening monophase and nanocomposite nitride and carbide coatings of WC, WN type. 2. X-ray optics, appliances. Production of X-ray protective layer by alloying of refined tungsten. |

| Molybdenum-tungsten alloy MW10-PM | Mechanical engineering and tooling industry. Hardening monophase carbide coatings for machine parts, cutting and forming tools. |

| Aluminum-titanium, aluminum-titanium-silicon composites |

1. Mechanical engineering and tooling industry. Hardening multi-phase and nanocomposite 2D and 3D nitride coatings for machine parts, cutting and forming tools. 2. Decorative coatings. |

| Nickel N1-PM | Mechanical engineering and electronics. Protective coatings for parts of machines and equipment. |

| Nichromium Cr20N80-PM |

1. Microelectronics. Resistive films of hybrid chips. 2. Production of low-emissive glass. Multilayer films of Ni-Cr/Ag/Ni-Cr type for glass. |

| Zink-gallium oxides (A-GZO) | Production of electroconductive, transparent layers for solar batteries, LCD, low-emissive architectural glass. |

2. Hardening surfaces for tools. Up-to-date materials for coatings.

According to State Corporation RUSNANO, consumption of metal-cutting tools in Russia in 2007 comprised $444 mln. At the same time the world average reached the level of $14 billion. The import share of the Russian market exceeded 57%. The experts anticipate growth of Russian metal-cutting tools consumption up to 10% per year during the period of 2010. In order to meet home market needs of tools and hardening surfaces, e.g. for processing of aircraft engine parts, RUSNANO approved the project for production of hard-alloy metal-cutting and nanostructured coatings based on NPA Saturn facilities on the 1st of September, 2008. It should reduce the level of dependence of internal mechanical engineering on the import of foreign tools. The project key technology is surfacing of tools with nano-structured coatings. The technology has been developed by Kurchatovsky Institute.

POLEMA JSC cooperates with RRC "Kurchatovsky Institute" and other leading research centers and enterprises in the sphere of materials for hardening coatings: RPC Elan – Praktik, GosNIImash, the Institute of physics of strength and material sciences, SC OMSKagregat, Moscow Power Engineering Institute “Research Center of Resistivity”, Artinsky factory, SKIF-M, Moscow Tools Factory, Tool engineering, RDC Materials and Technologies, TOMSK Research Institute of Atom Physics and other Russian and foreign companies.

Examples of vacuum nano-composite coatings, structure and properties are mentioned in RPC Elan-Praktik survey at the company’s website. The company applies dual magnetron sputtering by means of equipment for production of 2D and 3D state-of the-art nano-composites. E.g. multi-functional coating nc-CrN/nc-AlN has hardness of 3700 HV, temperature resistivity below 1150 0С, friction coefficient per steel -0,25. The structures of TiAlN/Si3 N4 , CrAlN/ Si3 N4 types have advanced properties. POLEMA also cooperates with the company in the sphere of chromium sputtering targets supply. POLEMA mastered production of planar targets made of Al-Ti composites for expansion of technological capacity and production of nano-composite and gradient coatings by magnetron sputtering method. Planar targets and Al-Ti composite discs could be produced under customers’ drawings.

Chemical composition, homogeneity, density and structure are the basic properties characterizing sputtering targets and evaporable sources. Chemical composition, interstitial impurities (C, O, N) and chemical homogeneity of evaporable and sputtering materials influence homogeneity of atom flow, properties and reproductive characteristics of deposited coatings. That’s why company produces items for thin films out of refined materials with purity of 99,95%.

Chemical composition of chromium ERCr-1, ERCr-O has unique purity. It is produced as flakes (plates) by means of chromium anhydride electrolysis and high-temperature hydrogen refinement. The grades are well-known for their thin shape, high density, purity and homogeneity, long-term storage without property change.

The typical chemical composition of refined chromium of ERCr 99,99 grade

| Element | µg/g | Element | µg/g | Element | µg/g |

| F | < 0,05 | Mn | 0,5 | Mo | 1 |

| C | 30 | Fe | 5 | Rh | < 0,05 |

| N | 10 | Co | 0,05 | Ru | < 0,05 |

| O | 20 | Ni | 2 | Pd | < 0,05 |

| S | 7 | Cu | 2 | Ag | < 0,05 |

| Na | 4 | Zn | 0,2 | Cd | < 0,05 |

| Mg | 0,5 | Ga | < 0,1 | Sn | < 0,1 |

| Al | 1 | Ge | < 0,05 | Sb | < 0,7 |

| Si | 6 | As | < 0,1 | Te | < 0,05 |

| P | < 1 | Se | < 0,5 | Ba | < 0,2 |

| K | < 1 | Rb | < 0,1 | W | 2 |

| Ca | 2 | Sr | < 0,1 | Re | < 0,1 |

| Sc | < 0,1 | Y | < 0,1 | Ir | < 0,05 |

| Ti | 2 | Zr | 1 | Au | < 0,05 |

| V | 5 | Nb | 2 | Pb | 0,05 |

| B | < 0,1 | Sm | < 0,1 | Bi | < 0,05 |

| Li, Be, In, Cs, La, Ce, Pr, Nd, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Hf, Ta, Pt, Tl, Th, U | < 0,005 each | ||||

Chromium, molybdenum, tungsten sputtering targets, titanium composites are produced by sintering technique or hot isostatic pressing (HIP) of internal metal powders. All sintered ingots are compressed (forging, pressure forming, rolling and extrusion) in order to get the specified microstructure, small or medium grains and apparent density of 99%. The chemical composition, microstructure, density of base materials, semi-finished products and final products are controlled at all stages of technological process. It ensures reproduction of physicochemical properties of stock-produced items.

Chromium ERCr 99,95-99,95.

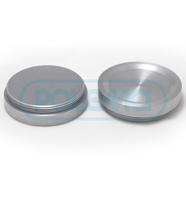

It’s produced as flakes and machined plates, discs, rings, cathodes, rods of different design under customers’ drawings.

Content of metal impurities: 500 ppm max of ERCr99,95-PM grade and 100 ppm max of ERCr99,99-PM grade. The content of O, N, C and S gas-forming impurities amounts to 200 ppm. The density is about 99% in comparison with moulded density (7,19 g/cm3). The medium grain size of homogeneous random-oriented microstructure is below 150 mkm.

Cr 99,95-99,99% products

Molybdenum M99-95-PM

It’s produced in the form of machined plates, discs, rods as per customers’ drawings.

Typical chemical composition

| Мо | Impurities, µg/g (ppm) | |||||||||

| 99,98 % | Fe | Na | Ni | K | Cu | Al | Si | C | O | N |

| 60 | 5 | 10 | 10 | 10 | 10 | 10 | 30 | 50 | 10 | |

Targets density is 99,5% min in comparison with moulded density (102 g/cm3). Homogeneous microstructure with the medium grain size of 30-80mkm.

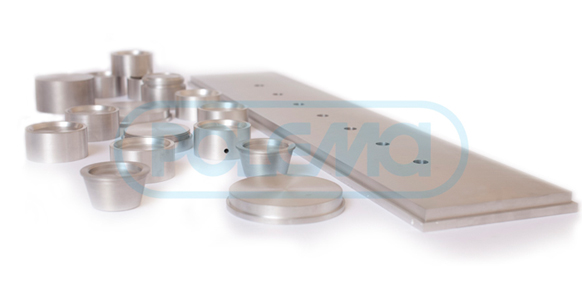

Molybdenum sputtering targets

W99,95-PM tungsten

It’s produced in the form of machined plates, discs, rods as per customers’ drawings.

Chemical composition. Typical composition of base element is 99,98% (excluding gas-forming impurities), of gas-forming impurities of O, N, C and S - 110 ppm.

Targets density is 99,5% min in comparison with moulded density (19,3 g/cm3). Homogeneous grain-oriented structure.

Aluminum-titanium, aluminum-titanium-silicon, aluminum-chromium composites.

Evaporable cathodes and sputtering targets made of Al-Ti, Al-Ti-Si, Al-Cr composites are new generation materials of POLEMA for hardening and wear-resistant coatings.

The materials have advanced technical properties. They allow to produce nitride single-layer and multi-phase nanocomposite structures (as well as in composition with other materials, e.g. chromium) of high temperature and wear resistance.

Apparent density of products is 99% max in comparison with moulded density. Homogeneous random-oriented microstructure with uniform distribution of components.

Al-Ti. Standard compositions of unobstructive products.

| Grade | Composition, at% | Chemical composition, mass % max. | ||||||

| C | N | O | S | Mg | Fe | Si | ||

| T43Al57-PM | Al/Ti 70/30 | 0,1 | 0,1 | 0,5 | 0,01 | 0,005 | 0,12 | 0,1 |

| T47Al53-PM | Al/Ti 67/33 | 0,1 | 0,1 | 0,5 | 0,01 | 0,005 | 0,12 | 0,1 |

| T54Al46-PM | Al/Ti 60/40 | 0,1 | 0,1 | 0,5 | 0,01 | 0,005 | 0,12 | 0,1 |

| T64Al36-PM | Al/Ti 50/50 | 0,1 | 0,1 | 0,5 | 0,01 | 0,005 | 0,12 | 0,1 |

Al-Ti-Si. Composition.

| Grade | Composition, at.% | Chemical composition, mass % max. | ||||||

| C | N | O | S | Mg | Fe | Ni | ||

| T43Al49К8-PM | Al/Ti/Si/ 61/30/9 | 0,1 | 0,1 | 0,5 | 0,01 | 0,005 | 0,15 | 0,1 |

Al-Ti products

Al and Ti distribution in composite Al/Ti 67/33 at.%.